ENGINEERING SERVICES

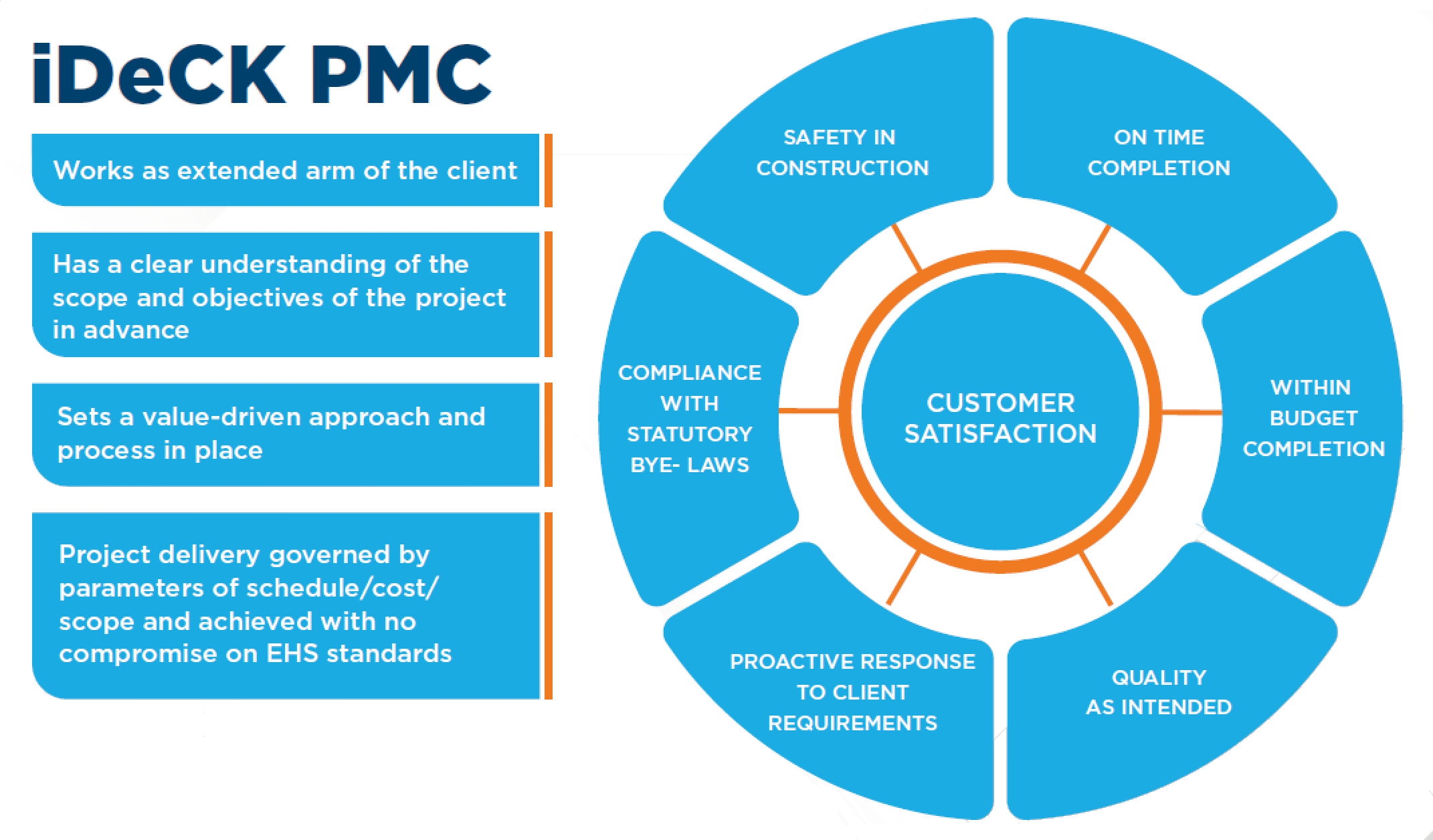

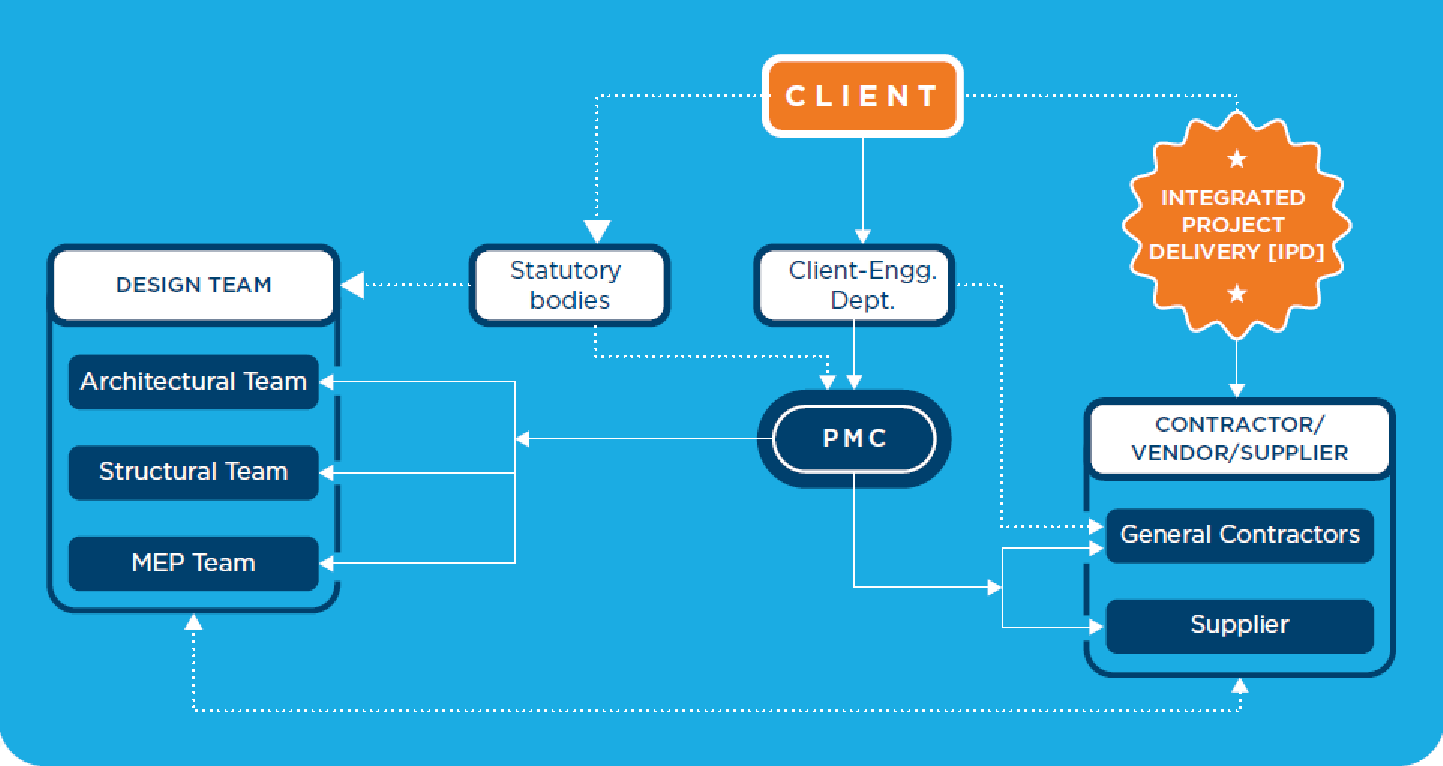

Every successful project begins with a blueprint for effective project management. This encompasses a structured process consisting of multiple phases with strategies, processes and tools to manage design and construction. Effective implementation includes controlling of key parameters such as scope, planning, design, scheduling, risk management, resource optimization etc.

Typical construction projects are spread across phases – pre construction, construction and post-construction phase. The iDeCK team brings an integrated approach to this including design management, coordination across disciplines, bid-process management, planning & scheduling, cost management, ITP/QC, SHE Compliance, testing & commissioning, MEP services and DLP service.

We ensure our execution standards adhere to the quality manual & SHE Manual with a specific emphasis on MEP services and applicable compliance. We have in place an effective tool for monitoring projects on a daily, weekly and monthly along with a transparent and accurate bill certification process. We also work on scheduling meetings with various stakeholders including consultants, clients, architects and vendors to assess the project’s progress.

PMC Activities

Project Communication,

Pro-Active Delivery Approach

1

Design

Management

- Review of design drawings for contractual compliance prior to issue as GFC

- Verification, validation & suggestions for improvement/optimization of the project

- Coordination of all services to ensure the project design and deliverables are aligned with the baseline schedule

- Ensuring applicable compliances

2 Contract Management

- Tender document finalization

- Pre-tender strategy

- Vendor qualification

- Tender floating

- Pre-bid meeting

- Technical bid evaluation

- Commercial bid evaluation

- Contract finalization

- Contract administration

3 Construction Management

- Preliminary project implementation plan

- Baseline schedules

- Design review & validation

- Quality plan

- SHE plan

- Risk analysis & mitigation

- Project team

- Establish project communication system

- Approval process

- Stringent meetings

- Project monitoring by tools

- Inspection & testing

- Measurements & billing

- Support client on all contractual issues, if any.

- Testing & commissioning

- As-built drawings & handing over

- Change order management – DLP starts

4 Project Close Out

- Punch in list de-snagging

- Facility commissioning & handing over notes

- O & M manual/close out

- Customer complaint

- Completion certificate

- As built drawing/project report

A Schedule Monitoring Progress & Cost

- Project quality plan

- Inspection test protocol

- Work method approval

- Sample/data sheet approval by T-committee

- Sub-contractor approval

- Workmen skill approval

- Mock up approval by T-committee

- Material Inspection by T-committee at site

- Site Inspection clearance formats

- Quality audit/Weekly QRM

- Compliance

B Quality Management

- Project HSE plan approval

- HSE plan integration of all vendors

- Job safety analysis review and approval

- Permits and third party testing

- Safety induction for workers of various agencies

- Motivation and continuous training

- Health and environment checklists, CSR initiatives

- Compliance to HSE norms as per regulations

- Audit & compliance

C Safety Management

- Sign off of master schedule

- Develop of schedule for engg., procurement & construction

- Individual vendor schedule sign off

- Resource mobilization schedule

- Weekly schedule review meeting

- Delay analysis/catch up plan

- Look ahead

- Escalation to respective stakeholders

- Continuous tracking